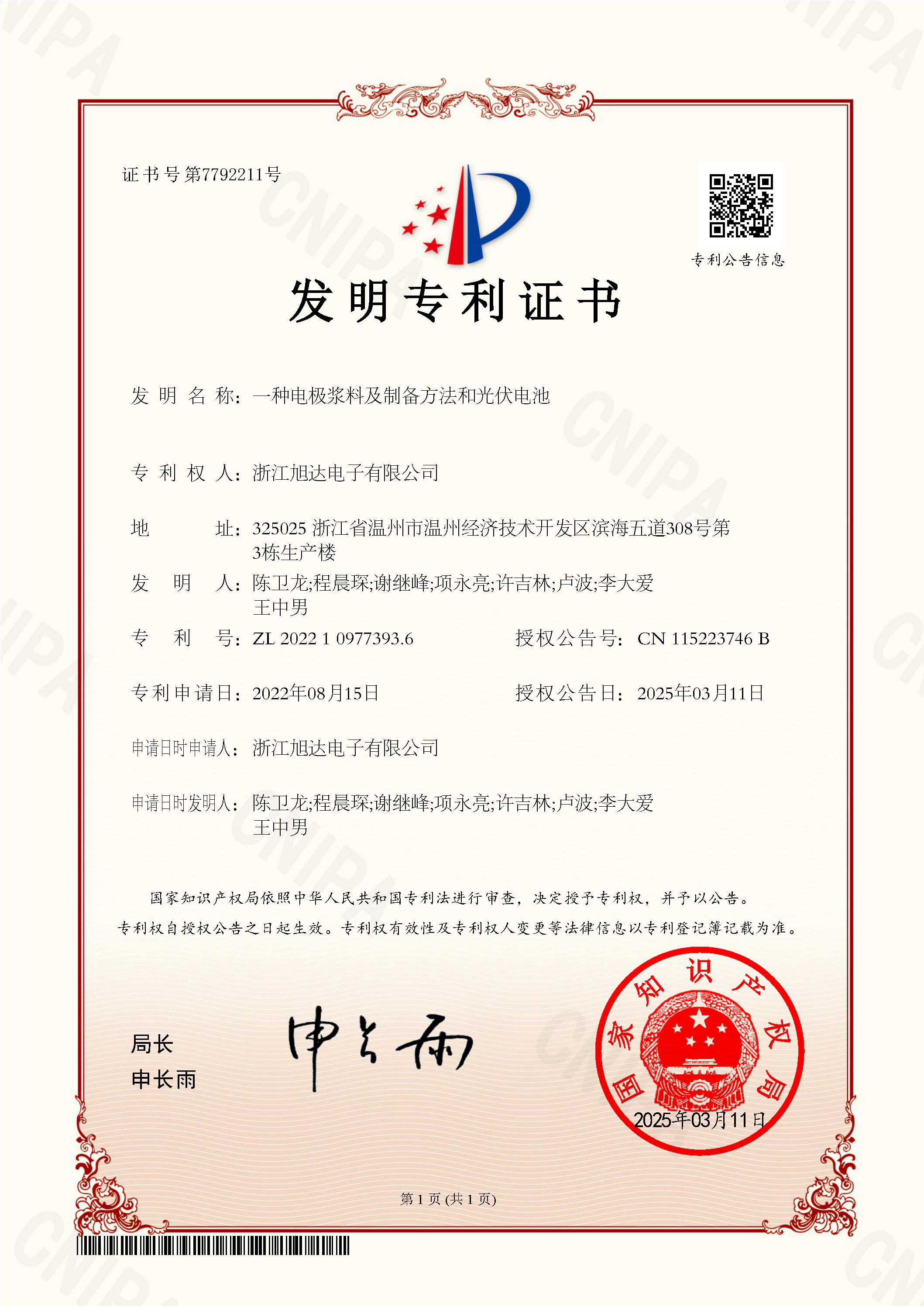

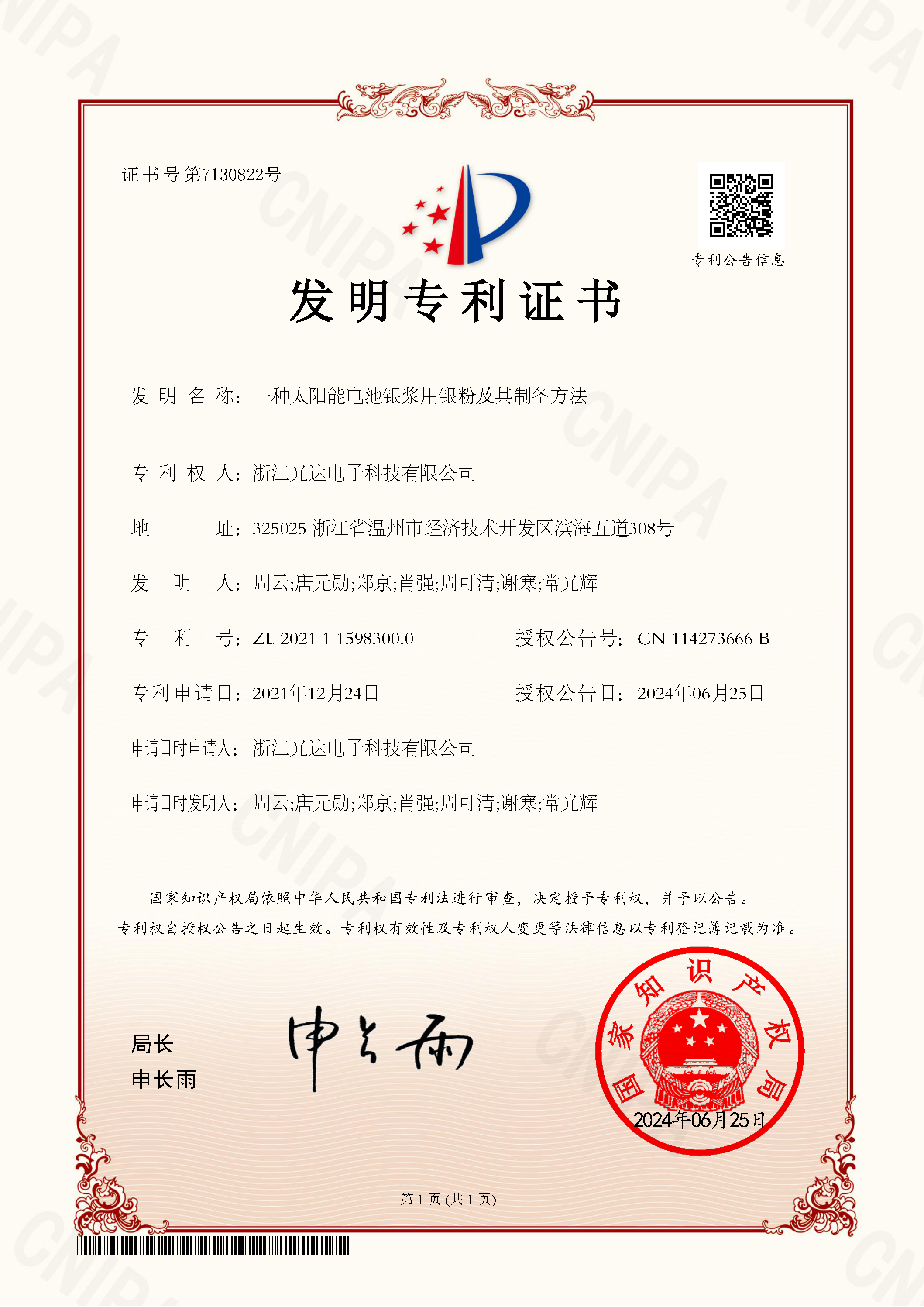

Established in 2010, Zhejiang Gonda Electronic Technology Co., Ltd. is an innovative high-tech enterprise engaged in the R&D, production, and sales of solar conductive pastes and electronic pastes. The company's leading products are front/back electrode pastes for solar cells and electronic pastes. In the solar paste field, it has multiple product models such as TOPCon front/back full sets of silver pastes, PERC silver pastes, HJT low-temperature pure silver and silver-clad copper pastes, XBC full sets of pastes, etc., which can meet the process requirements of different technology routes.

The company has integrated R&D and production capabilities for silver paste products, with complete independent R&D and production of three main materials: silver powder, glass powder, and organic carriers. It is the world's unique material-independent R&D and production type paste supplier. The company has always adhered to the "1-meter width, 100-meter depth" specialized, refined, peculiar, and new development path to ensure product superiority and stability, meeting customers' high-quality and rapidly developing market demands. Through 15 years of long-term R&D investment, its products have reached a leading level in the industry, widely used in solar cells, electronic components, automotive, IoT, 5G communications, and other fields.